I hate to beat a dead horse, so I won't. I do feel the need to bring up the subject of CSST bonding once again, however, because there are a few details that I haven't covered in the past. Instead of just blogging about those details, I'm re-writing my last post on this topic and including the new information.

First, a primer on CSST, which stands for Corrugated Stainless Steel Tubing. If you own a newer home or you’ve recently had gas lines added to your home, there’s a good possibility that CSST was used. This is a relatively new, flexible material that is approved for the distribution of natural gas inside of homes. The best analogy I can think of to describe this material is that CSST is to steel gas pipes what PEX is to copper tubing, or Romex® is to rigid metal conduit.

CSST needs to be bonded. The most common issue that home inspectors find with CSST is a system that hasn’t been properly bonded. When CSST is installed without being properly bonded to current standards, there is an increased risk for damage to the material from a nearby lightning strike. When CSST is damaged, it can leak gas and cause an explosion and/or a fire. To the best of my knowledge, all manufacturers of CSST began implementing specific bonding requirements around 2006. Click the image below to see a large version of the installation tag from Gastite dated August 9, 2006.

What about existing installations? Building codes have something called ‘grandfathering’. This means that if something was installed to code, it’s still a code compliant installation today, even if the codes have changed significantly. The nice thing about being a home inspector is that I don’t need to get hung up on code requirements. If something is deemed unsafe due to a change in accepted residential construction standards, my Standard of Practice requires me to report on it, whether it met code at the time that it was installed or not.

If CSST was installed to code in 2005 and the manufacturer didn’t have any special requirements for bonding at the time it was installed, the installation still meets code today. That won’t stop me from recommending this important safety upgrade, however. I’ll still recommend having the system bonded to today’s standards. The manufacturers of CSST have changed their installation requirements because they’ve learned that the old methods weren’t good enough. There is an unacceptable risk of fire from a nearby lightning strike with older systems.

Where does CSST need to be bonded, inside or outside of the house? It's safe to have CSST bonded either inside or outside the house. There has been some confusion on this topic because early editions of the 2015 International Fuel Gas Code said the following: "7.13.2.1 The bonding jumper shall connect to a metallic pipe or fitting between the point of delivery and the first downstream CSST fitting." The revised edition of the same codebook has been reworded to say the following: "7.13.2.1 The bonding jumper shall connect to a metallic pipe, pipe fitting, or CSST fitting." That's the language I'll use. For the record, that section of the fuel gas code equates to section 310.1.1 of the Minnesota Fuel Gas Code, which uses the 2012 International Fuel Gas Code. In other words, our relatively new code language is already outdated.

Not only does the newest version of the code allow CSST to be bonded anywhere, but CSST manufacturers also allow CSST to be bonded anywhere. For example, Gastite says "The bonding clamp attachment point may be at any location within the gas piping system."

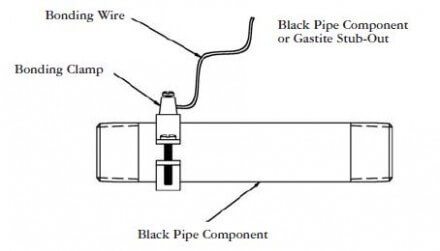

What does proper bonding look like? There needs to be a separate bonding wire connected either to the rigid gas piping before the CSST, or directly to one of the CSST nuts. This is needed any time CSST is installed, even if it’s just a small amount. The diagram below shows an example of what this would look like when properly installed to today’s standards.

The photo below shows an example of CSST bonded at the exterior of the home, with the bonding clamp connected to the CSST nut.

The other end of that wire shown above went into the main electric panel. The video below, produced by Gastite, shows a couple of examples of properly bonded CSST.

While the old method for bonding CSST required a connection at the main electric panel, this is no longer required in Minnesota. Minnesota’s 2015 Fuel Gas Code uses the 2012 International Fuel Gas Code, which requires CSST to be bonded anywhere along the electrical service grounding electrode system. That means that the bonding conductor for CSST can be connected to the metallic water piping coming into the home, a ground rod at the exterior, or anywhere else on the service grounding electrode system. This change makes it much easier to properly bond CSST. To view the current requirement, click the following link to view Chapter 3 of the 2015 Minnesota Fuel Gas Code, and scroll all the way down to the bottom to view section 310.1.1.

One place that isn't a proper bonding location is the intersystem bonding terminal, which can be found at the exterior of homes that have been built in accordance with the 2008 NEC or later. That version of the NEC was the first to require an intersystem bonding terminal for low-voltage communication equipment such as television cables, satellites, and phones.

Some manufacturers of CSST offer a product with a black outer “arc-resistant” jacket, which is designed to show that it’s an arc-resistant product. Two such examples of these products are CounterStrike® and FlashShield™. While the manufacturers of these products do not require special bonding, the Minnesota Fuel Gas Code makes no exception to the bonding requirements for these products. Both products still need to be bonded. For more info on that topic, check out this document on CSST bonding from Pro-Flex.

Side note: I heard a rumor that the city of Maple Grove does not allow the installation of CSST. I called their building inspections department to ask about this, and was told that they only allow the installation of arc-resistant CSST products, such as FlashShield™. The reason for this is that they're not comfortable with the installation instructions for the other stuff, which says "Care should be taken when installing vertical runs to maintain as much separation as reasonably possible from other electrically conductive systems in the building. There is no requirement to maintain separation from other electrically conductive systems when routing FlashShield™"

When building officials have asked the manufacturer how much distance is required, the manufacturer has left it up to the building official. Building officials aren't in the business of testing manufacturers products for safety; that's supposed to be the manufacturer's job. Because the manufacturer would not give an answer to this question, the city of Maple Grove simply won't allow this product.

How can you know if you have CSST in your home? Look for flexible tubing with a yellow or black jacket that covers the ridges. CSST either has a yellow jacket or a black jacket. This material is not to be confused with an appliance connector, which might have a yellow coating that follows the contours of the ridges. The photo below shows the two different materials.

The bottom line is that if you have a home with CSST, you should make sure it’s properly bonded to today’s standards, regardless of whether the installation ‘met code’ when it was originally installed. Also, if your electrician tells you that bonding the CSST may increase the risk of a lightning strike or is safe because it meets code, simply thank them for their time and call a different electrician.

Additional Information on CSST and bonding

- Basics of CSST – a brief description, a brief history, and some basic installation requirements

- CSST: Direct Bonding Required for All Brands

- Cutting Edge Solutions – this web site is filled with information related to CSST bonding requirements.

- Validation of Installation Methods for CSST Gas Piping to Mitigate Indirect Lightning Related Damage – the conclusion of this report says “With a sufficiently short bonding conductor, arcing is suppressed entirely, and the possibility of an arc discharge perforation is eliminated.”

Also, here’s an old news clip of me talking to Kare 11 news about CSST bonding: